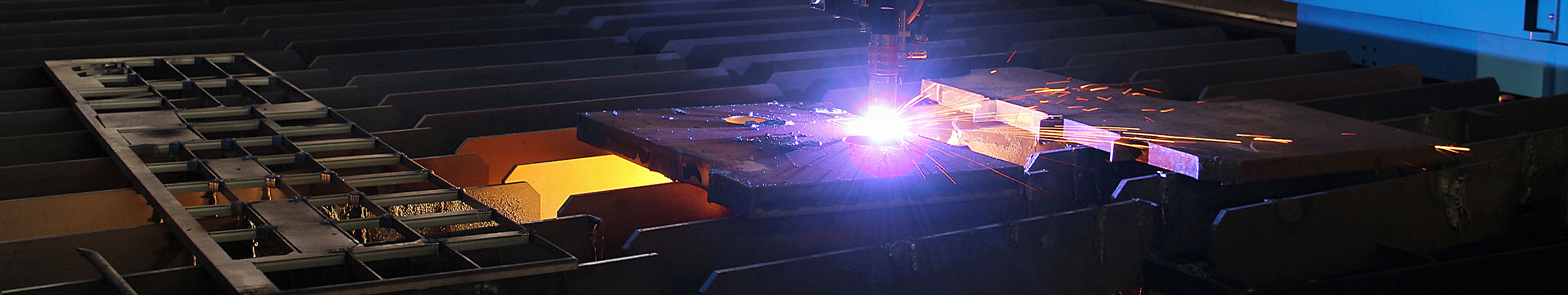

Sectional extraction tables

Tigemma extraction tables

We deliver Tigemma sectional extraction tables for cutting metal sheets with the thickness up to 200 or 300 mm and length of the exhausted section of 515 mm. The extraction table is used for storing material, capturing the cutting dast and extraction of pollutants during shape cutting of materials with oxy-fuel and plasma systems. Its modern design with automatically switched sections in connection with an optimized exhaustion and filtration guarantees an efficient and effective protection of your workplace.

Equipment of tables Tigemma

- Exchangeable lamellas in the upper frame of the table are designed to store the material, which has to be cut. Their design is determined according to the cutting technology.

- The grid under the bars captures tiny cut-outs.

- Removable dust trays allow easy and fast cleaning of the table.

- The sectional extraction saves energy and lowers investment costs required for exhaustion and filtration.

- The design and shape of interior parts facilitate the subatmospheric pressure evenly distributed along the entire extracted section.

- The automatic control consists of a roller lever valve and a double-acting air cylinder, which secure the opening of the required part of the extraction table.

- The side air channel enables the extraction of individual sections and the connection with filtration device.

Kemper extraction tables

Company Kemper offers a comprehensive range of extraction tables for thermal cutting of materials.

KemTab Basic tables

The KemTab Basic extraction tables are an affordable solution for cutting metal sheets up to 50 mm thick (75 mm for a short time). The standard package includes fixed, unchangeable table dimensions, a mechanical control of the extraction flaps, support frames for material and slag trays and fitting for connection of extraction. The individual modules of the system are divided into segments. The control of each segment flaps is via control carriage, which opens only that section, where cutting is taking place. The table can also be supplied with mechanical flap control.

KemTab Advance tables

The KemTab Advance tables provide a robust and flexible solution for cutting metal sheets up to 150 mm thick. The modular design and arrangement in standard widths and lengths makes it possible to build nearly every required table size. The standard equipment includes pneumatic control of the exhaust flaps, material support frame and slag tray. The individual system modules are divided into segments. Flaps activation of the respective segment is carried out via control carriage. The exhaust flap control allows only that section to be open where cutting is taking place.

KemTab HiEnd table

The KemTab HiEnd is designed for plasma cutting operations with a capacity of up to 600 A and materials up to 300 mm thick when using oxy-fuel technology. Large, reinforced slag trays ensure quick cleaning and guarantee minimum downtime.

KemTab Vibro table

The KemTab Vibro extraction table with automatic discharge system enables significantly longer intervals between cleaning cycles, which greatly reduces operating costs. The table is suitable for cutting current up to 400 A and material thicknesses up to 150 mm.

KemTab Flex tables

The KemTab Flex extraction tables offer a cost effective solution and the same advantages as the extraction tables KemTAB Basic. The high flexibility is based on easy transport and subsequent assembly. The modular design of the table KemTAB Flex facilitates the maintenance and cleaning of the table. Large slag trays ensure quick cleaning at longer cleaning intervals.

.

Do you need more information? Contact us!